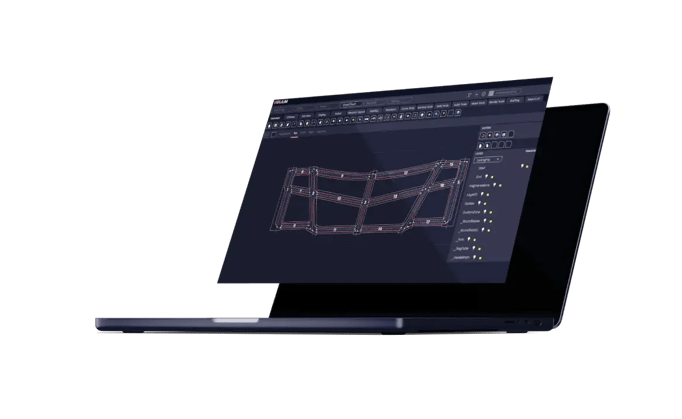

Turns your part’s preform into executable RoboWAAM code, with our advanced slicing and trajectory strategies.

WAAMPlanner integrates with our other metal additive manufacturing software. It works with WAAMKeys for automatic calculation of process parameters; WAAMSim for path simulation and collision detection; and WAAMCtrl to which it passes all the process information to assess parts quality as RoboWAAM builds them.

We initially tried to work with existing providers of Computer Aided Manufacturing software, but we could not achieve the efficiency and rigour we wanted for our customers. That is why we have developed WAAMPlanner from the ground up, with additive manufacturing in mind, based on almost two decades of successful part-building history at Cranfield University.